Discover how to choose the right Router Bits for every kind of material

Router bits for wood, are they all the same?

No, not really. Let's see the answer together. Each material has different specific requirements and therefore requires an appropriate tool with a different geometry, cutting edge inclination and much more. Before discussing about router bits, let us look at the main types of wood and wood derivatives in order to understand what makes these materials so different. While it is not possible, to fully detail every material available on the market, you should know that Klein has a solution for every needs.

Wood Types and recommended Router Bits

Wood: There are many types of wood and its derivatives; generally it is a soft, porous material. Klein router bits are made from special steel or solid carbide, both of which offer an excellent balance of finishing and router bit life. Some router bits are coated with a special treatment, others are made entirely of Widia, and finally some are made of PKD (polycrystalline diamond).

- Router bits for softwood: Generally this type of wood comes from conifers such as fir, pine, or larch. These trees grow rapidly compared to others, the color of the wood is bright with regular grain and a porous texture. Easy to work compared to hardwood, it is suitable for numerous applications: carving, cabinetmaking, woodworking, furniture, fixtures, and more.

- Router bits for hardwood: A wood from slow-growing trees, the density and strength are greater both on the surface and in the structure. Beech, chestnut, cherry, walnut and many others fall into this category each with different colors, grains and characteristics.

- Router bits for exotic wood: This is what woods from countries located in tropical, equatorial regions or far from the territory where we are, Europe in this case, are called. The colors, hardness and grain of these woods are unique; it is important to consider the environmental impact related to deforestation and choose only wood from sustainable sources. A few examples of exotic woods: Iroko, Wenge, Ebony and many more.

Team Klein strongly believes that in order to work with wood and use a router bit, one must have technical knowledge. We are there to help anyone who wants to get closer to this world because we know what it means to be a fan of woodworking.

Panel types and specific router bits

We have mentioned the types of wood, now we move on to panels. Let's explore the most common types of panels that can be found in major DIY stores, both large superstores and smaller stores. Understanding the material you are buying is crucial to choosing the correct router bit; anyone who tells you that the router you are buying is good for any material and processing is only interested in selling you the product.

Router Bits for MDF and HDF

MDF (medium density fibreboard) / HDF (high density fibreboard) and chipboard: these are among the most abrasive common materials that quickly wear out the router bits cutting edge. PKD (polycrystalline diamond) Router Bits and solid carbide cutters are better for these materials. It doesn't mean that router bits with a 8 or 12 mm shank with brazed HW tips are not able to work these materials, but they have definitely technical limits regarding the durability of the cutting edge and the final result of the finishing after many hours of work.

Laminated and bilaminated boards

All boards with a single side are called laminates, while if there is a shett on both sides, they are called bilaminates. Using a high-quality tool is crucial with laminated and bilaminated boards. Why? The bottom sheet is particularly subject to tearing and cracking. Therefore, with a low-quality tool, the risk of tearing the laminate is much higher.

Other types of boards and wood

- Plastic coated Boards: Wood, chipboard or MDF panel with a layer of paper treated with melamine resin.

- Phenolic Coated Boards: Wood, chipboard or MDF panel with a layer of paper treated with phenolic resin

- Veneered Boards: Panel coated with a thin sheet of premium wood to achieve the effect of solid wood at a lower cost.

- Melamine Boards: Chipboard, MDF or wood coated with several layers of pressed and heat-treated paper, which are thicker and stronger than laminated panels like Phenolic Boards ord Plastic coated boards.

- Plywood Boards (raw): Semi-finished product made by overlapping several layers of wood glued together. It is widely used in industry because it offers good resistance, it is light and cheap and most importantly, it is easy to work. Its shortcoming is its poor resistance to humidity. Beware of buying poor quality panels, the glues used could be a problem during processing.

- Plywood Boards (lower quality grade): Very similar to plywood panels but much less resistant, in fact there are fewer layers of wood and less thickness.

- Lumber, scrap wood or Timber (firewood): Lumber can often be associated with carpentry wood used on building sites during the construction of buildings or similar. This wood often has residues of concrete or plaster, nails or screws which makes it ‘dangerous’ during working unless using a special tool. Waste or recycled wood are those pieces of wood often coming from pallets or other small structures that once disused are reused in other ways. Timber is commonly firewood or similar.

OK, so what router bit should I choose for the laminate or bilaminate panel then?

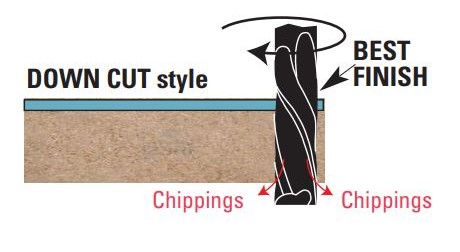

Down cut spirals

for an excellent finish on the top side of the panel pushing wood chips downward

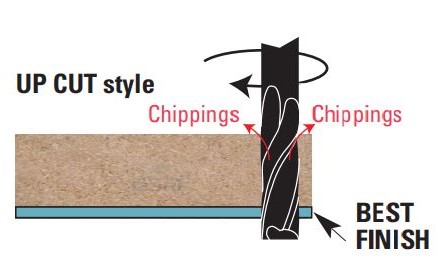

Up cut spirals

for an excellent finish on the bottom side of the panel pushing wood chips upward.

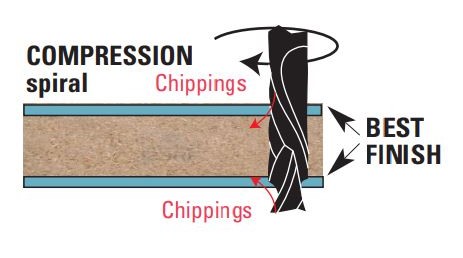

Compression spirals

for an excellent finish on both sides of the panels, especially on laminates and double-sided melamine (UP & DOWN).

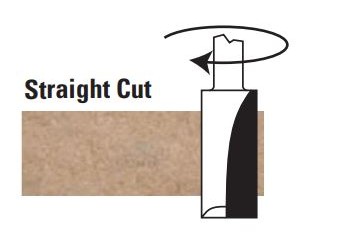

Straight Tips

Standard HW straight bits

NUMBER OF TEETH:

- Z=1: allow heavy duties on soft materials and an excellent chip evacuation

- Z=2: allow a better finish on hard materials and a good chip evacuation

- Z=3: allow an excellent finish on all types of materials

- Z=2/Z=3 with chipbreaker:: ideal for heavy duties

- Z=3: with semi finishing chip-braker execution

N.B.: Increasing the number of teeth should increase also the feed speed in order to preserve the tool from burning or early wearing out.

What does the Klein Team suggest?

We suggest these two Router Bits: T166 and T168

T166: Solid carbide compression cutter with 2 ball bearings. Excellent board finish thanks to the right-hand rotation and the compression helix, the double ball bearings on top ensure greater precision with hand portable router-machine. Ideal for bilaminated boards, plywood and similar wood boards. This cutting edge design is less aggressive on wood and allow a perfect finish with smooth cuts.

T168: HW Flush trim bits with double ball bearings. Perfect panel finishing due to its upcut spiral that pushes chips upward, preventing tears in the woodboards. Designed for a professional work and those those who need to work on the bottom side of the board. This Cutter greatly reduce the risk of tearing and damaging the wood while working, it is designed to trim wood.

Router bits for planing and rabbeting with portable router

WC190.350.R – Router bit with 8mm shank and 35mm diameter with interchangeable knives.

Or

C175.350.R – Router bit with a 8mm shank and and HW brazed tips.

The C175.350.R is included in our New Router bits Master Set X018 e X019, the first with 6 items and the second complete with 12. Both Sets are designed for those who want to star working with wood. All in a comfortable recycled wood box, a much more environmentally friendly solution than router bit sets stored in plastic packaging.

The Top of the range for large industries and more: KleinDIA

Click here and Discover more – Specifically designed to exceed the limits of classic router bits, they have an increased tool life up to 4-6 times. Solid carbide cutters with an anti-friction coating treatment that guarantees the best performance on the market. Not just for industries, they are also available with 8mm shank for portable routers for professional craftsman, such as T143.080.RKD

Do you still have doubts?

Contact us

Just remember to tell us: what material you are working, what machine you are using. the more details you provide the better the answer we can give you, Thank you!

Italiano

Italiano English

English Français

Français Deutsch

Deutsch Español

Español